Risk assessment

IRCPack carries out studies for the risk assessment of toxicological and sensory damage and the drafting of “dossiers" to support the declaration of compliance with Regulation (EC) No. 1935/2004 of the european Parliament and of the Council of 27th October 2004.

The Regulation (CE) No. 1935/2004, at the Art. 3 states that

«Materials and articles, … shall be manufactured in compliance with good manufacturing practice so that, … they do not transfer their constituents to food in quantities which could:

(a) endanger human health;

(b) bring about an unacceptable change in the composition of the food;

(c) bring about a deterioration in the organoleptic characteristics thereof.»

In order to declare the conformity with Reg. (CE) No. 1935/2004 (Art. 3) it is necessary to demonstrate that the packaging does not give anything unsafe from the toxicological point of view and that there is not any organoleptic change.

Therefore, it is necessary to go beyond the analytical checks required by the Regulations for the specific materials (overall and specific migrations, composition and purity requirements) to be able to prevent the risk of contamination.

EVALUATION OF ORGANOLEPTIC DAMAGE RISK

It is carried out through sensory analysis that allows to understand if the packaging is able to maintain unaltered the organoleptic characteristics.

IRCPack has a trained panel and these tests are conducted according to the methods established by UNI Standards:

• UNI 10192 standard: olfactory and gustatory analysis

• UNI EN 1230-1 and 1230-2 standards: olfactory and retro-taste and retro-odor analysis

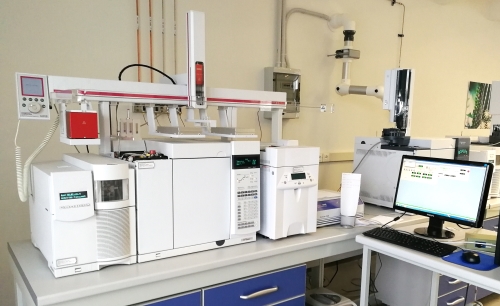

Any organoleptic changes can be investigated by gas chromatography /mass spectrometry (GC/MS) studies.

EVALUATION OF TOXICOLOGICAL DAMAGE RISK

It is carried out by monitoring volatile, semi-volatile and non-volatile organic compounds at different stages of the process (for example, neutral material – printed material), with the aid of special instrumental techniques based mainly on GC/MS.

The analytical survey is focused on specific targets (expected compounds, such as the residual solvents in flexible packaging), on screening for the identification and quantitative evaluation of each compound detectable by the analytical technique used.

The evaluation protocol, carried out by Sepack Lab, provides:

• I level screening analysis

⋅ identification and semiquantitative evaluation of volatile organic compounds on the total sample

⋅ identification and semiquantitative evaluation of semi-volatile and non-volatile compounds on the total sample

• II level screening analysis

⋅ identification and semiquantitative evaluation of organic compounds on the inner side, by single-side contact with different simulants, for example isothane, ethanol, poly (2,6-diphenyl-p-phenylene oxide) (MPPO or Tenax®).